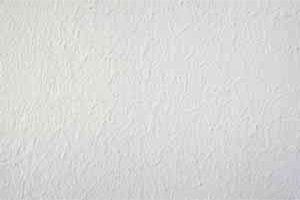

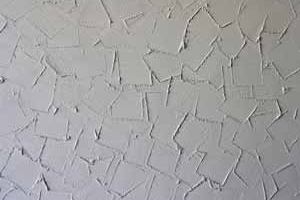

Textured Coatings (Artex)

Textured coatings, (often referred to as Artex) were widely used in the UK in the 1970s and 80s.

Artex is actually a brand name of Artex Ltd in the UK, however the name was widely used to describe other products by other manufacturers. The popularity of textured coatings prior to asbestos being fully banned in 1999 meant that the finish had been widely used in both commercial and domestic properties.

Until the mid 1980s, asbestos was used in textured coatings to improve strength, however it should be assumed that any coatings known to have been installed up until 1999 should be assumed to contain asbestos fibres as a precaution. Textured coatings to not pose a threat to health if left undisturbed as fibres are only released when in a powdered form such as when a ceiling is sanded or drilled. Textured coatings are usually painted which is a form of encapsulation, offering additional protection. Textured coatings typically contain less than 5% asbestos and Chrysotile was the only fibre to be used which poses the least risk of all types of asbestos.

Dangers of Textured Coatings (Artex)

Textured coatings pose minimal risk to health if kept in a good condition and well maintained. The likelihood of fibres being released is very low unless the surface is damaged or is being worked on. Often the case with ceilings containing Artex, the risk of collapse due to water ingress or leaking service pipes poses the biggest risk in terms of emergency works being required.

Removing Textured Coatings (Artex)

Professional advice is advisable when dealing with textured coatings. Although covered by the Control of Asbestos Regulations 2012, many cases involving their removal fall within exemptions to the licensing requirements meaning a licensed contractor is not required. Although removal by a licensed contractor is not a requirement in most circumstances, care should be taken when working with any kind of textured decorative coatings as risks are still present. For large-scale works, a notifiable non-licensed work (NNLW) form should be completed and returned to the HSE.

At the very least, those working in the area must wear appropriate disposable Personnel Protective Equipment (PPE) and Respiratory Protective Equipment (RPE). The area should be sealed to reduce the risk of further contamination and any area of the textured coating being worked on should be wetted first to further reduce the potential for fibre release. Any surfaces below the work area should also be covered to reduce contamination.

If you are in any doubt about any Artex or textured coating, then get in contact. Further information and guidelines can be sought from the HSE. To find out more about asbestos removal, navigate to the appropriate section.

Styles of Artex